Industry Application Cases

Industry Application Cases

daily necessities series

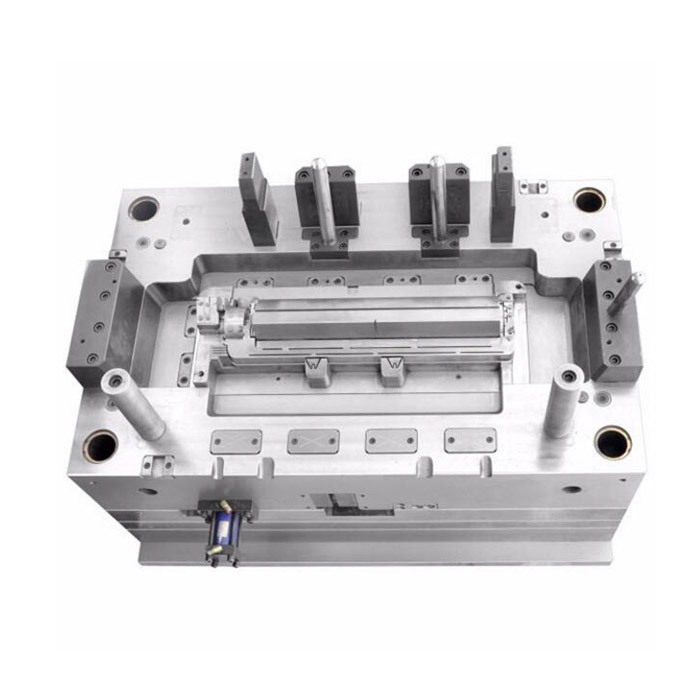

Industrial Products Series

Multicolor mold series

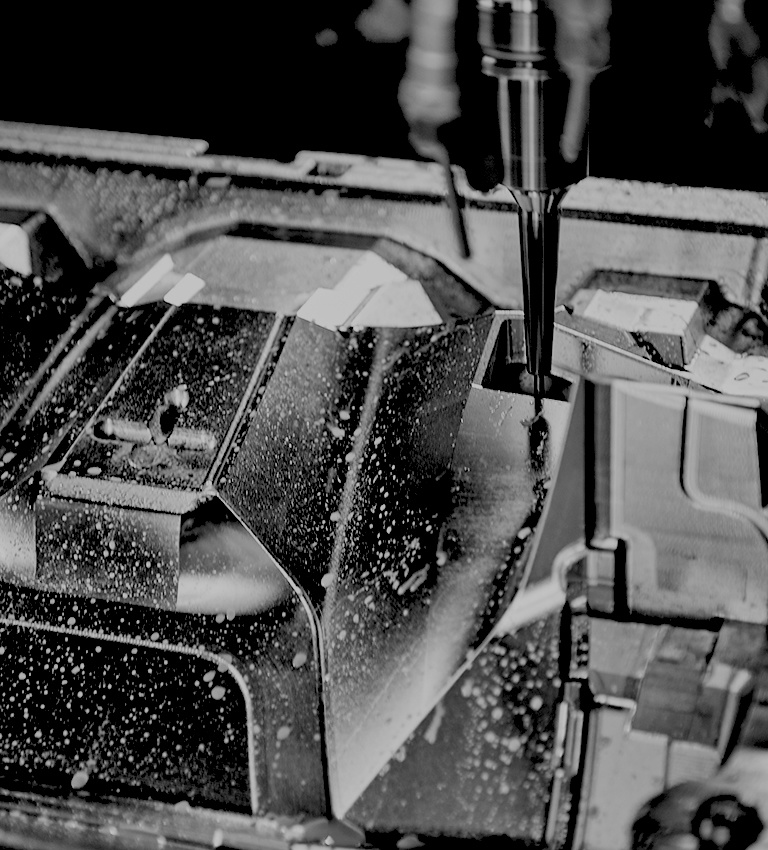

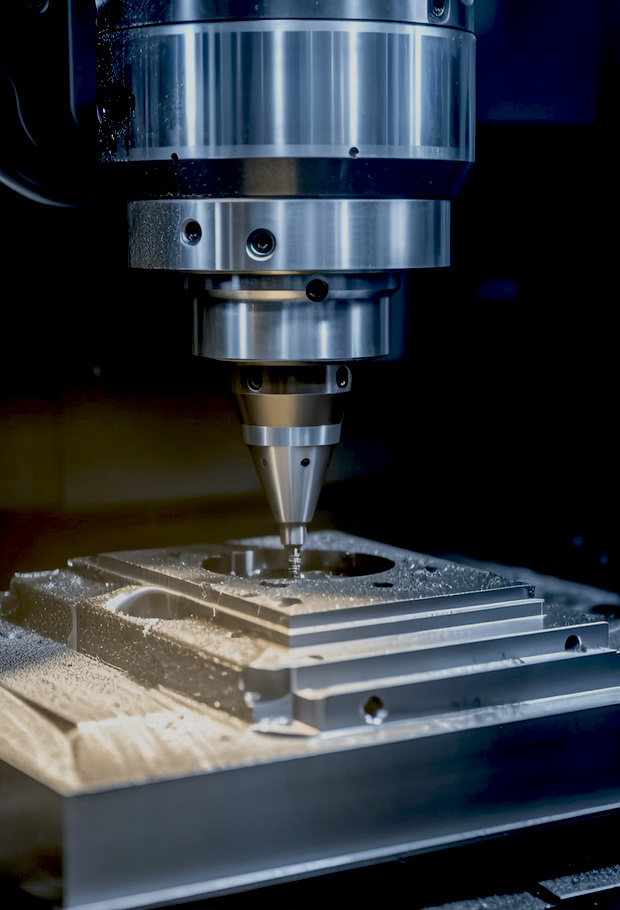

Mold intelligent manufacturing

Our Capabilities

Our Capabilities

Our Capabilities

Info & Events

Company News

Industry Insights

FAQs

What should I prepare for an inquiry?

You might need to send us the 3D/2D modeling data of the product, or send us the product sample.

How much does it cost to make a mold?

Each mold is customized according to customer needs, we can quote you a reference price within 24 hours after receiving your data or sample.

How long does it take to manufacture the mold?

This depends on the complexity of the mold. The more complex the mold, the longer the processing time required. We will give you an estimated leadtime together with the quotation.

What plastic material should I use for my product?

Different industry applications have different requirements for plastic materials. If you were not sure which type of material to use, we will recommend material type according to your requirements.

I have one sample only, can I make the mold?

Yes, we can develop a 3D model by reverse engineering, to build its mold.

I have 2D drawings only, can you make the mold?

Yes, we need you to provide 2D drawings as detailed as possible, which contain all aspects of the size and shape of the product. We can generate the 3D drawings accordingly.

How do I determine which kind of steel I need to make my mold?

The selection of steel type is mainly determined by the chemical properties of the plastic you want to used for the product. We can offer suggestions of the proper steel according to your specific needs.

How to choose the right injection machine for production?

We can help to analyze your products using professional software and recommend the appropriate injection conditions according to the results, so as to help you to select the most suitable machine.

How do I know if a hot runner system or not? What are hot and cold runners?

Hot runner is a commonly used auxiliary technology in the mold runner system. The use of hot runner technology in the mold can obtain better product quality and faster production cycle than when it is not used. A mold that does not use hot runner technology is correspondingly called a cold runner mold. If you were not sure whether to use hot runner in your mold or not, we will conduct professional analysis for your product to help you.

How do I determine the number of cavities in a mold?

We can help to choose the proper mold cavity quantity according to your production plan and injection molding machine conditions.

![[Exhibition] InterMold/InterPlast Thailand 2024 [Exhibition] InterMold/InterPlast Thailand 2024](https://omo-oss-image.thefastimg.com/portal-saas/new2023122011554873440/cms/image/dea81c04-24d3-4554-b61e-ca32650bb8ba.jpg)