Project Management

Tooling Process

Project Discussion

01

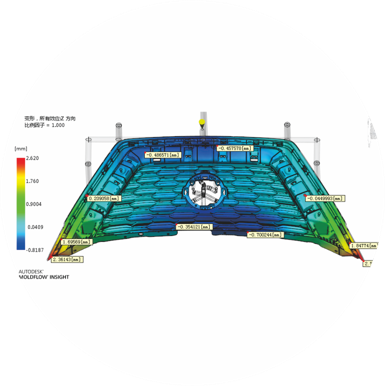

Part Analysis

02

Optimization

03

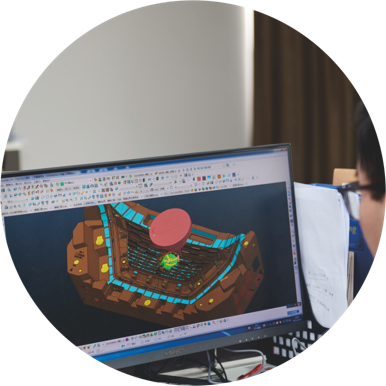

3D build

04

Machining

05

Inspection

06

Assembly

07

Spotting

08

Inspection

09

Looking forward to helping you

Continuously improve customer satisfaction

Continuous improvement is the means, customer satisfaction is the standard

Customer satisfaction is the standard of product quality. We listen to the voice of customers, grasp the needs of customers, customer satisfaction to define quality standards, and try our best to improve customer satisfaction and loyalty.

Quality Management

The company has got ISO9001:2015 quality system certification, and is running under 6S management requirements.

Selected Material

Only qualified steel materials can make a qualified mold meeting the various requirements of different plastics. Incoming materials need to be inspected carefully to check if all technical parameters are passed before entering the next stage. Our steel materials are all from well-known suppliers both in domestic and abroad markets to ensure the high quality.

Narrow Tolerance Machining

From conventional CNC to 5-axis high-speed ones, we keep using the most advanced machineries for our manufacturing. Meanwhile their operators are requested to strictly comply with operation procedure and norms to achieve a high machining precision. Furthermore, every step of machining must be finished within tolerance limit, follow specified processing techniques and sequences.

Strict Checking

Strict inspection criterions are applied throughout the whole manufacturing. With various measuring instruments, components from every step of machining will be checked carefully to make sure they are complied with a narrow tolerance level. Requirements from customer will also be followed closely. Our project specialist will check machining plans carefully before project kick off to ensure every requirement detail will be applied.

Inspection Criterions

From material to a single mold component, they will all go through a series of inspection criterions check, making sure everything from every section is qualified to enter the next step of manufacturing.

Fast delivery

We place great emphasis on efficient management, because we understand the great importance to deliver the molds to our customer on time.

Electronic project management

Your every single project will be followed by a specially-assigned engineer, taking control of the process schedule, and keeping every machining step on track.

By adopting customized mobile applications, we have most of the procedure paper works digitalized. From the project manager to the front lines, the whole project status can be monitored simply by checking their apps at any time, enable every possible factor that might cause a delay to be found and eliminated in time.